When it comes to maintaining your dually truck, tire rotation is a task that should be high on your list. But “How to rotate tires on a dually” might not be as straightforward as it seems. Due to the distinctive design of dually trucks, with their dual rear wheels, the rotation process is different from that of standard vehicles.

The purpose of this guide is to demystify the steps and highlight the importance of rotating your dually tires correctly, ensuring even wear and tear, prolonged tire life, and optimal driving performance. Whether you’re a seasoned truck owner or new to the world of heavy-duty vehicles, understanding the correct rotation pattern and procedure is crucial to maintaining your dually’s integrity on the road.

Table of Contents

ToggleUnderstanding the Importance of Tire Rotation for Dually Trucks

Regular maintenance is key to keeping your dually truck running smoothly and efficiently. Among the most critical yet often overlooked maintenance tasks is tire rotation.

Understanding how to rotate tires on a dually not only ensures optimal performance but also extends the life of your tires, saving you money and time in the long run. Tire rotation for dual trucks involves a specific process due to their dual rear wheels, which requires a keen understanding to perform correctly.

What is a Dually, and Why Does it Need Regular Tire Rotation?

A dual truck is a vehicle equipped with dual rear wheels on each side, designed to carry heavier loads and provide greater stability. This unique configuration means that the tires experience wear in different patterns compared to standard trucks.

Regular tire rotation is crucial for dual trucks to balance the wear on all tires, maintain even traction, and improve overall ride quality. Ignoring this critical maintenance task can lead to premature tire wear, reduced fuel efficiency, and even safety hazards.

Defining a Dually: Dual Rear Wheels for Extra Support

The term ‘dually’ refers to the twin wheels set on either side at the rear of the truck, providing additional support for heavy-duty tasks. These extra wheels increase the weight distribution across a broader surface area, allowing for the transport of heavy loads without overburdening the vehicle.

However, this added support comes with increased responsibility; to keep these dual wheels in top condition, a strategic tire rotation schedule is vital.

The Role of Tire Rotation in Extending Tire Life and Performance

Tire rotation is an essential practice that directly impacts the longevity and performance of your dually’s tires. By regularly rotating the tires, you ensure that each tire wears down evenly. This not only extends the life of the tire but also maintains the stability and performance of your truck.

Proper tire rotation on a dually requires moving the tires in a specific pattern that differs from single rear wheel vehicles, which is fundamental to reap the benefits of even tire wear and sustained performance.

Benefits of Proper Tire Rotation on Dually Trucks

Regular and proper tire rotation on dually trucks is more than just a maintenance ritual; it’s a crucial practice that brings a myriad of benefits, ensuring that your heavy-duty vehicle performs safely and efficiently.

From extending the life of your tires to saving on fuel and maintenance costs, the advantages of adhering to a tire rotation schedule are substantial.

Even Tire Wear and Extended Tire Life

Rotating your tires on a dually truck promotes even wear across all six tires. The rear tires on a dually bear more weight and are prone to wear faster, especially when hauling heavy loads. By rotating the tires, you distribute the wear more evenly, which can significantly extend the life of the tires.

Regular rotation means less frequent replacements, providing a clear economic benefit while keeping the tread depth uniform, which is essential for maintaining traction and performance.

Improved Fuel Efficiency and Handling

A dually truck with uneven tire wear may experience reduced fuel efficiency. Tires with uneven wear create more rolling resistance and, consequently, require more power to move the truck. By ensuring your tires wear evenly through rotation, you can maintain optimal fuel efficiency.

Furthermore, tires that receive regular maintenance and exhibit even wear contribute to improved handling and stability. This is particularly crucial for dually trucks, considering their heavy loads and distinctive driving dynamics.

Safety Enhancements and Cost Savings

One of the most critical benefits of tire rotation is the improvement in vehicle safety. Evenly worn tires provide better grip and are less likely to fail suddenly, reducing the risk of accidents.

Additionally, with regular tire rotation, potential issues can be identified and addressed before they turn into costly repairs. This proactive approach to tire maintenance ensures that your dually truck is not only safe to operate but also more economical in the long term, saving you money on both tires and fuel.

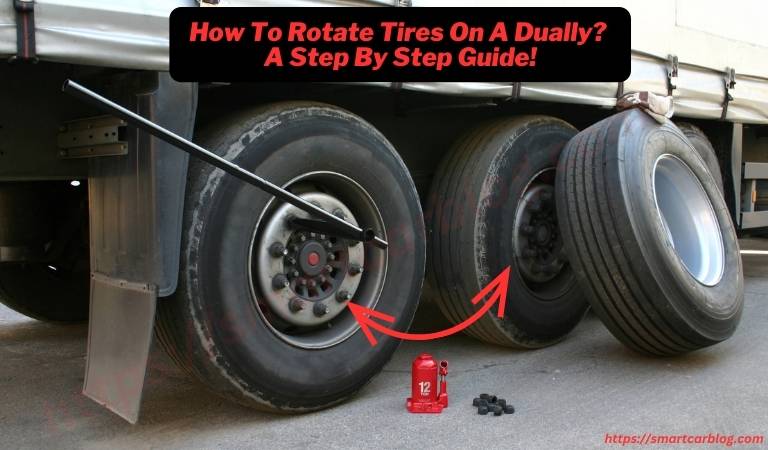

How to Rotate Tires on a Dually: A Step-by-Step Guide

Tire rotation on a dually truck is a vital process that not only extends the lifespan of your tires but also ensures your vehicle maintains its performance and safety on the road.

Understanding how to rotate tires on a dually is critical, as the process can differ significantly from that of standard vehicles. This guide will walk you through each step, ensuring that you’re well-equipped and prepared to tackle the job with confidence.

Preparing for Tire Rotation: Tools and Safety

Before diving into the rotation process, it’s important to prepare by gathering the right tools and understanding the safety measures necessary to prevent accidents.

Preparation is key to a smooth and successful tire rotation, ensuring that everything is in place to facilitate an efficient and safe maintenance task.

Essential Tools for the Job

To rotate the tires on your dually truck, you will need a set of tools that are capable of handling the heavy-duty nature of the task. The essentials include a high-quality jack capable of lifting a dually truck, jack stands for stability, a lug wrench or impact wrench, and wheel chocks to prevent the truck from rolling.

Ensure that these tools are rated for the weight of your vehicle and are in good working condition before you begin.

Safety Precautions Before You Begin

Safety should never be compromised when performing vehicle maintenance. Before starting the tire rotation, park your dually on a flat, stable surface and apply the parking brake. Use wheel chocks on the tires that you won’t be rotating first to keep the truck in place. When lifting the vehicle, ensure that the jack is properly positioned under the truck’s designated lift points to avoid damage or accidents.

Always use jack stands to support the vehicle’s weight—never rely on the jack alone. Finally, put on suitable safety gear such as gloves and protective eyewear, and never position any part of your body beneath the vehicle unless you have securely supported it with jack stands.

Identifying Your Dually’s Tire Rotation Pattern

Tire rotation is crucial for the maintenance of your dually truck, but it’s not a one-size-fits-all procedure. The pattern in which you rotate the tires can vary based on your specific vehicle setup and the manufacturer’s recommendations.

Identifying the correct tire rotation pattern for your dually is essential to ensure even tire wear and optimal performance. Let’s explore how to determine the right rotation strategy for your heavy-duty hauler.

Different Rotation Patterns for Different Dually Setups

Dually trucks come with different configurations, and the tire rotation pattern you choose should correspond to your particular setup.

Generally, there are several recognized patterns, such as the rearward cross, the X-pattern, or the forward cross. Experts often recommend the rearward cross for vehicles with dual rear wheels, where the rear tires move directly forward and the front tires cross to the opposite sides of the rear.

However, the specific pattern may also depend on whether your dually is two-wheel drive (2WD) or four-wheel drive (4WD) and if the tires are directional or non-directional. Being aware of these variations is the key to executing tire rotation correctly on your dually truck.

Consulting Your Owner’s Manual for Specific Guidelines

While general patterns can serve as a guideline, the best practice is to consult your dually truck’s owner’s manual for the manufacturer’s specific recommendations. The manual will provide precise instructions tailored to your vehicle’s design, taking into account the dually configuration and the type of tires fitted.

It will also indicate the recommended rotation intervals, which can vary based on your driving habits and the loads you typically carry. Adhering to these guidelines ensures that tire rotation contributes to the longevity and safety of your tires, as well as the overall handling of your dually truck.

The Tire Rotation Process for Dually Trucks

Proper tire rotation is essential for the longevity and performance of your dually truck’s tires. Due to the dual rear wheels, this process can be more complex than on standard vehicles.

Understanding the correct method for rotating the tires will ensure that you’re doing the job safely and effectively. This comprehensive guide will take you through the necessary steps to rotate your tires like a pro.

Lifting Your Dually Safely

Lifting your dually safely is paramount to ensuring a smooth and successful tire rotation process.

This detailed guide on how to lift your dually securely emphasizes the importance of safety at every step.

Positioning the Jack and Lifting the Truck

Before you begin:

- Ensure that your dually is parked on a level surface and that you have engaged the parking brake.

- Locate the truck’s jack points, which are typically indicated in the owner’s manual.

- Place the jack securely under the designated point and lift the truck until the tires are just off the ground.

You must do this step with care to avoid any slippage or instability.

Ensuring Stability Before Tire Removal

Once your dually is lifted, place the jack stands under the frame or axle for added security. Never rely on the jack alone to hold the weight of the truck, as this poses a significant safety risk.

The stands should be rated for your vehicle’s weight and properly positioned to support the truck firmly before you proceed with removing the tires.

Removing and Rotating the Tires

Properly removing and rotating the tires of your dually is essential for even wear and a prolonged lifespan.

Follow these detailed steps to effectively remove and rotate your dually tires, ensuring optimal performance and safety on the road.

The Correct Order of Tire Swapping

The tire rotation pattern on a dually truck typically involves moving the front tires to the rear and the rear tires to the front in a specific order. If your dually is a 4WD, it may require a cross-pattern rotation.

Begin by loosening the lug nuts on one wheel, then move on to the next, following the sequence laid out in your owner’s manual or a trusted maintenance guide. Once all wheels are appropriately swapped, you can begin to tighten the lug nuts in a star pattern to ensure even pressure.

Tips for Keeping Track of Tire Position

Keeping track of which tire goes where can be confusing. A simple tip is to label each tire with a piece of chalk or a tag before removal, indicating its new position.

This way, you can ensure that each tire is rotated to the correct location. Remember also to check the tire pressure and adjust it if necessary before lowering the truck back to the ground.

Re-installing and Securing the Tires

Once you have rotated the tires to their new positions, the next step is to securely re-install them. This stage is critical as the safety of your vehicle depends on the proper attachment of the tires to the wheel assembly.

Torque Specifications and Proper Tightening

Tighten the lug nuts to the manufacturer’s specified torque settings rather than simply tightening them as much as possible. This ensures uniform mounting of the tires and proper performance under the stress of the vehicle’s weight and on-road forces.

Use a torque wrench to tighten the lug nuts to the exact specification outlined in your dually’s service manual. Typically, you’ll tighten them in a crisscross pattern, which helps the wheel to seat evenly against the brake drum or rotor.

Double-Checking Your Work for Safety

After mounting the tires and initially tightening the lug nuts, lower the truck until the tires make contact with the ground, and then apply the final torque setting. This prevents the wheel from turning as you apply the final torque. After fully lowering the truck and ensuring all tires are on the ground, go around each tire once more to double-check that all lug nuts are properly torqued.

This step is essential; a loose wheel can lead to a dangerous situation on the road. Finally, it’s a good practice to re-check the torque after 50 to 100 miles of driving, as lug nuts can settle in and may need a final tightening to maintain the correct torque.

Post-Rotation Checklist for Dually Trucks

After rotating the tires on your dually truck, there are several key steps you should follow to ensure the job has been done successfully.

A thorough post-rotation checklist can help you confirm the safety and readiness of your vehicle before you hit the road. Let’s break down this checklist to cover all the necessary inspections.

Inspecting Your Work: Ensuring a Successful Tire Rotation

Once the tires are back on your dually and you’ve tightened the lug nuts to the correct torque, it’s important to inspect your work. This involves a series of checks that can prevent future problems and ensure that your tire rotation contributes to a smoother ride and longer tire life.

Visual Inspection and Tire Pressure Check

Begin with a visual inspection of the tires and wheels. Check for any obvious issues like missing lug nuts, visible damage to the tires or rims, and ensure that the tires are seated properly on the wheel hubs.

Follow this with a tire pressure check. Incorrect tire pressure can lead to uneven wear, reduced fuel efficiency, and can compromise the truck’s handling. Adjust the tire pressure to the manufacturer’s recommended settings to help maintain optimal performance.

Test Driving and Monitoring for Issues

The final step in the post-rotation checklist is to take your dually for a test drive. This allows you to feel how the truck handles with the newly rotated tires. During the test drive, listen for any unusual noises and pay attention to the vehicle’s handling. Any vibrations or pulling to one side could indicate that the tires have not been installed correctly or there’s an imbalance.

After the test drive, it’s advisable to check the lug nuts again to ensure they haven’t loosened from the motion of the drive.

By diligently following this post-rotation checklist, you can drive with confidence, ensuring that you properly maintain the tires of your dually truck for maximum safety and efficiency on the road.

Maintenance Records and Scheduling Next Rotation

Maintaining a regular tire rotation schedule is key to prolonging the lifespan of your tires, especially for a dually truck that handles heavy loads. It’s not just about the actual rotation process; keeping detailed records and planning for future rotations are equally important to ensure consistent performance and safety.

Documenting Your Tire Rotation for Future Reference

After each tire rotation, it’s crucial to document the date, mileage, and any observations noted during the process. This log can be kept in your vehicle’s maintenance book, a dedicated app, or a digital spreadsheet. Record the torque values applied, tire pressure adjustments made, and any issues encountered during rotation.

This information is invaluable for tracking the wear pattern of your tires and can provide insights into your vehicle’s condition over time. In addition, should any warranty issues arise with your tires, your maintenance records will be essential in supporting your claim.

When to Plan Your Next Tire Rotation

Determining the ideal time for your next tire rotation depends on several factors, including your dually truck’s manufacturer recommendations, the type of tires, your driving habits, and the loads you typically carry. A general rule of thumb is to rotate your tires every 5,000 to 8,000 miles.

However, always refer to your truck’s owner’s manual for the most accurate interval specific to your model. Marking the next rotation date on your calendar or setting a reminder on your phone can help ensure you take advantage of this crucial maintenance task.

By diligently documenting each tire rotation and scheduling the next one, you maintain a crucial aspect of your dually truck’s upkeep, which can save you time and money in the long run. Accurate records and a consistent schedule are cornerstones of responsible vehicle maintenance that can lead to a smoother ride, improved safety, and peace of mind on the road.

Troubleshooting Common Issues After Rotating Tires on a Dually

Rotating the tires on your dually is an essential maintenance task, but sometimes issues can arise post-rotation. Recognizing and addressing these problems promptly can prevent further complications and ensure your vehicle remains in top condition.

Identifying and Resolving Post-Rotation Problems

After rotating the tires on your dually truck, it’s important to stay vigilant for any signs of issues. Early detection is key to resolving potential problems before they escalate. Keep an eye (and ear) out for any changes in your vehicle’s handling or any new noises, as these can be indicators of an issue related to the recent tire rotation.

Vibration or Wobbling After Tire Rotation

One common issue you might encounter is a vibration or wobbling sensation, particularly at higher speeds. Several factors, such as improperly torqued lug nuts, imbalanced tires, or incorrectly seated tires on the wheel hubs, could be causing this issue. To rectify this, first, check the lug nuts with a torque wrench to ensure they’re at the correct tightness.

If the problem persists, the tires may need to be balanced. This is a precise process that usually requires professional equipment, so you might need to visit a tire specialist.

Unusual Tire Noise or Tread Wear Patterns

Another concern could be new noises coming from the tires or irregular tread wear. These issues could be indicative of misalignment or suspension problems that were masked by the previous tire positions.

If the noise is a humming or grinding sound, it may be related to the tire tread or internal damage to the tire. On the other hand, uneven tread wear often indicates alignment issues that require professional assessment and correction.

When to Seek Professional Assistance

Tire rotation on a dually truck, while manageable as a DIY project, sometimes necessitates the expertise of a professional. Knowing when to seek help can save you time and protect your vehicle from potential damage.

Challenges Specific to Dually Tire Rotation

Rotating tires on a dually is more complex than a standard vehicle due to its dual rear wheels. Challenges such as aligning dual wheels properly, handling heavy tires, and ensuring balanced torque can be daunting for those without the right tools or experience.

If you experience persistent issues such as uneven tire wear, vibration, or handling problems after performing a DIY rotation, consider it a sign that you may need professional assistance. These symptoms can indicate deeper issues that require a professional’s touch, such as precise wheel balancing, alignment, or even suspension work.

Finding a Trusted Mechanic for Your Dually

When it’s time to call in a professional, finding a trusted mechanic who has experience with dually trucks is paramount. Look for service centers that specialize in heavy-duty vehicles or those with positive reviews from other dually owners.

A skilled mechanic, equipped with the necessary knowledge and tools, will ensure the correct performance of tire rotation and any related services tailored to the unique needs of your dually.

They can also provide valuable insight into the specific maintenance schedule and needs for your vehicle, helping you to keep it in peak condition for the long haul.

Last Verdict: How to Rotate Tires on a Dually

Regularly performing tire rotations on a dually truck is a crucial aspect of maintaining your vehicle, and you should prioritize it. This process, which demands the appropriate tools, knowledge, and precautions, can be carried out at home.

However, at times, it may necessitate the expertise of a professional. To cap it all, if you’re comfortable with the task, ensure you have a comprehensive understanding of the rotation pattern, the necessary tools, and safety measures. Remember to perform post-rotation checks, such as verifying tire pressure, lug nut torque, and a test drive to detect any abnormalities.

However, given the intricacies associated with dually tire rotations, there’s no shame in turning to a professional. This is especially recommended if you face persistent issues post-rotation or if you need more confidence in your ability to perform the task safely and correctly.

In essence, whether you choose to undertake this task yourself or enlist professional help, the key takeaway is that regular and correct tire rotation is indispensable. It extends the life of your tires, improves fuel efficiency, and, most importantly, keeps you safe on the road. So, when it’s time for your next tire rotation, weigh your options, consider the challenges, and choose the path that ensures the job is done right.

FAQ: How To Rotate Tires On A Dually?

Q: What is the correct way to rotate tires on a dually truck?

A: To properly rotate tires on a dually truck, you need to follow a specific rotation pattern that usually involves switching the front and rear tires on one side of the vehicle. In contrast, the rear tires on the opposite side change places with each other. Always consult your vehicle’s manual for the exact pattern.

Q: How often should I rotate the tires on my dually?

A: You should rotate the tires on your dually approximately every 5,000 to 8,000 miles. However, check your owner’s manual or ask a professional mechanic for the best interval for your specific model and usage.

Q: Can I rotate dually tires myself, or should I get a professional?

A: While you can rotate dually tires yourself if you have the necessary skills and tools, seeking professional help ensures the job meets precise standards, especially if you’re unfamiliar with the process.

Q: What tools do I need to rotate my dually’s tires?

A: You’ll need a heavy-duty jack, jack stands, a torque wrench, an impact wrench or tire iron, and wheel chocks to safely and effectively rotate your dually tires.

Q: Why is it important to rotate tires on a dually?

A: Regularly rotating tires on a dually ensures even wear, extends tire life, maintains balanced handling, and promotes better fuel efficiency.

Q: What safety precautions should I take when rotating my dually’s tires?

A:Before starting the tire rotation:

- Always park the truck on a level surface.

- Use wheel chocks.

- Securely lift the truck with appropriate jack stands.

Q: Do all dually trucks follow the same tire rotation pattern?

A: No, tire rotation patterns can vary depending on the make and model of the dually truck. It’s essential to consult the truck’s manual for the recommended pattern.

Q: How do I know if my dually tires have been rotated correctly?

A: After rotating, check for a smoother ride, even tire wear, and ensure there are no vibrations or unusual noises, indicating a successful rotation.

Q: What should I do if I experience vibration after rotating my dually’s tires?

A: If you notice vibration after a tire rotation, it may be due to imbalanced tires or improperly torqued lug nuts. Recheck the torque on all wheels and consider having the tires balanced.

Q: Can tire rotation on a dually affect my truck’s alignment?

A: Tire rotation should not affect alignment, but it can bring to light any existing alignment issues. If you notice uneven tire wear after a rotation, have your truck’s alignment checked.

Welcome to SmartCarBlog.com! I’m Rashel Miajee, The proud founder of smartcarblog.com. This is a part of

Welcome to SmartCarBlog.com! I’m Rashel Miajee, The proud founder of smartcarblog.com. This is a part of